Policy Effectiveness and Industry Culture

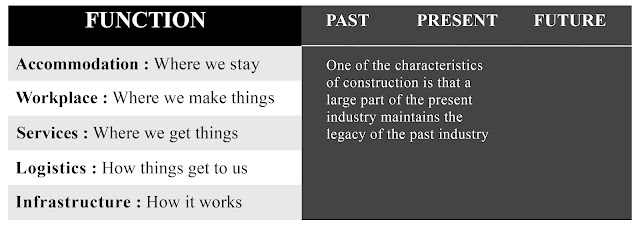

The broad categories of residential building, non-residential building and civil engineering have wide ranges of customers and projects and are different enough to call for different types of contractors and delivery processes. Therefore, they should be regarded as separate industries. The distribution of projects, firms and output all support the idea that construction is a collection of industries, not one single industry, albeit with overlaps between them. The combinations of products, parties and processes are distinct, so it is important to recognise that these differences exist and they need to be taken into account by government, industry and researchers. Considering construction as a single industry leads to analyses and prescriptions that may be appropriate to some parts of construction but are certainly not applicable to all. Government policy needs to recognise their differences.

Separating construction into three industries provides a different perspective on the long history of attempts to reform or transform construction in the UK. The UK reform movement is particularly well documented, there are a dozen reports between 1944 and 1998 summarised and discussed in Murray and Langford (2003), who concluded those reports agreed on the poor performance of construction with minor differences between their explanations for poor performance and recommendations for improvement. The last two of those reports by Latham in 1994 and Egan in 1998 became particularly influential as the UK government became the leading advocate of reform.

The public sector is typically the largest client of construction, although procurement is typically widely distributed across departments and levels of government, so it is not surprising the construction reform movement was led by government with inquiries, commissioned research and funding for demonstration projects. Although the reports discussed many issues, such as productivity, quality, training, contracting and documentation, the fundamental issue was the cost of construction, reflecting the UK government’s role as both a major client and the initiator of the inquiries and research. However, contractors typically had limited involvement in the inquiries and reports, and private sector clients largely stayed at arm’s length from the public sector’s reform strategies.

That this series of reports (and many others not included in Murray and Langford 2003) were required, averaging over two a decade for 50 years, shows how ineffective they were in developing policies to address the issues raised. The explanation for this policy ineffectiveness offered by Latham and Egan is industry culture, broadly seen as the custom and practices underlying the business model in UK construction. Latham focused on procurement and contractual relations with recommendations to change an adversarial culture, calling for more collaboration between clients, contractors, subcontractors and consultants, and more cooperative practices. He recommended ‘Partnering’ between clients and contractors to realise this.

Egan began his report arguing industry improvement required changing the industry culture, recommending lean production methods using examples from car manufacturing, steel-making, grocery retailing and offshore engineering by promoting offsite manufacturing in the Modernising Construction (National Audit Office, 2001) and Accelerating Change (Strategic Forum for Construction, 2002) reports, and supported the reform movement with legislation and by establishing Rethinking Construction, Construction Best Practice and the Movement for Innovation, which were brought together in 2004 as Constructing Excellence “to achieve a step change in construction productivity by tackling the market failures in the sector and selling the business case for continuous improvement. Through focused programmes in Innovation, Best Practice Knowledge, Productivity and Engagement, Constructing Excellence has developed a strategy to deliver the process, product and cultural changes that are needed to drive major productivity improvements in the sector.”

Prior to Egan the reform movement relied on industry participation, with little effect on how projects were procured and delivered. Contractual relationships were the focus of much of the reform agenda to improve industry performance. Egan introduced benchmarking against best practice to improve productivity, and Constructing Excellence documented demonstration projects. Murray and Langford thought the “demands on the industry cannot be met and so lead to an industry that cannot attract staff to deliver buildings on time, with increased costs and questionable quality.” (2003: 7). Other critics attacked the reform movement for its technocratic and managerial approach (Green et al. 2002) and the language used (Fernie et al. 2006). More relevant was a review of progress since Egan by Wolstenholme (2009), which found there had been little change in the industry: clients still awarded projects to the lowest bidder while contractors offloaded risks and maximised profits.

Sixty-five years after the Simon Committee report on building contracts (the first in Murray and Langford)Wolstenholme again called for cultural change “to integrate and embrace the complex picture of how clients and contractors interact” (2009: 8). Industry culture is clearly important, but it is also clear that culture is not malleable and does not change easily or quickly. A better explanation for the lack of impact of these reports, their recommendations, and the ineffectiveness of public policy in reforming construction is required. Simmons (2015) blames the policy making process as resistant to evidence and subject to ministerial whims and churn, with issues becoming politicised once they enter public debate. Carroll (2010) suggests that regulatory proposals typically don’t have a convincing evidence base and there is poor integration of impact assessment with policy development processes. Wond and Macaulay (2010) argue that generic ‘problem-inspired’ strategies developed by central policy-makers have to be interpreted by the ‘problem-solving’ implementers responding to nuances of local context and capability.

Construction is better viewed as three industries when the differences between residential building, non-residential building and engineering construction are taken into account. If the culture in each of the three industries is different, recommendations and policy directed at construction as a single industry are unlikely to be relevant across the three, and will thus be disregarded by many firms and clients. Clients are also different and can be generalised as households, businesses and the public sector, and their relationships with contractors varies accordingly. Another example is design, where house builders have pattern books, commercial building uses architects, and infrastructure is designed by engineers. These structural differences between the three industries affects the way clients, contractors, designers and suppliers will interact, thus each industry has developed individual characteristics over time that become that industry’s culture. The specific nature of these industry cultures makes recommendations and policy directed at construction as a single industry ineffective.

With separate industries and separate cultures, separate policies are required. A broad industry policy of the sort that targets construction as a single industry will be challenged by three deeply entrenched cultures with limited similarities.Research and reports that treat construction as a single industry have the same problem, although there is an economic activity called construction in the SIC the characteristics of the three sectors makes them different industries.The manufacturing SIC includes glass, wood products, steel, plastics and concrete, but they are regarded as separate industries and are not grouped together under a construction products SIC. An industry policy for the steel industry is not thought to apply to plastics or concrete because it is not relevant to those industries.

More recent construction policies in the UK have moved on from the industry culture debate, although the government’s objective to improve construction productivity through better procurement remains. With the launch of the Government Construction Strategy 2011-2015 and the Government Construction Strategy 2016-20 increasing the use of BIM became the target. The 2011 policy required BIM Level 2 across centrally funded construction projects by 2016, with BIM operating within the existing construction contractual framework using a legal agreement (the CIC BIM Protocol) added to professional services and construction contracts. The 2016 strategy required Level 3 BIM for public projects. BIM maturity levels were defined as:

· No BIM: Information is generated manually by hand

· Level 0: Basic 2D Computer-Aided Design (CAD) use for minimal collaboration.

· Level 1: Use of 3D and 2D CAD for documentation and works information.

· Level 2: Models are shared between the project team using a common data environment.

· Level 3: Wholly integrated information model across the project, with the team working collaboratively in real-time.

The Government Construction Strategy was within the broader UK Industrial Strategy, which included Construction 2025 and targeted a 33% cost reduction in the initial costs of construction and whole life cost of built assets, 50% faster delivery from inception to completion for new build and refurbished assets, 50% lower greenhouse emissions on construction projects, and a 50% reduction in the trade gap for construction products and materials. Further initiatives to support the policy were the Centre for Digital Built Britain in 2017, at the University of Cambridge, and the Construction Innovation Hub in 2018, a collaboration between the Centre for Digital Built Britain, BRE and the Manufacturing Technology Centre with £72m in government funding develop digital and manufacturing technologies in construction. The UK Industrial Strategy was revised in 2017 and included funding for a Construction Sector Deal, with the government committed to using Modern Methods of Construction through offsite construction for relevant departments from 2019. This was followed by the publication of Transforming Infrastructure Performance by the Infrastructure and Projects Authority (2017, updated 2021), setting out a long term programme to improve performance and delivery. Finally, in 2018 a BIM Framework based on a new ISO 19650 series of standards was released.

Ten years after the launch of the Construction Strategy progress towards BIM Level 3 remains patchy. Architects, engineers and large contractors in the UK have adopted BIM faster than services engineers, facilities managers and smaller contractors employing less than 50 people. One annual survey found nearly half the 200 respondents used BIM infrequently and thought adoption of was proceeding slowly, the other half used BIM often or very often. Only 6% thought progress was rapid, although 14% were using ISO 19650. Another 2021 survey by the UK BIM Alliance with over 1,100 respondents found 65% were implementing BIM and used it on around half their projects and 30% were using ISO 19650. However, over half the subcontractors and cost consultants, and over 40% of project managers and facility managers, were not implementing BIM. Nevertheless, 56% of respondents thought BIM would become business as usual in 3-5 years and the other 44% thought it would take longer. Any industry strategy that approaches a technology adoption target of 100% in less than two decades has to be regarded as effective.

Compared to the limited effects of the construction reform movement’s promotion of MCM and offsite manufacture, which remains confined to niche markets, the BIM strategy has seen a significant increase in the use of BIM and the UK is seen as a leader in adoption. The government mandate on use of BIM on public projects has been much more effective in 10 years than six decades of exhortations and recommendations to change industry culture. Recognising this, the provision of clauses covering contentious issues in construction contracts (such as intellectual property and data ownership) worked with rather than against industry practice and culture. The BIM Framework provided a roadmap for the firms and clients and the development of standards provided a toolkit.

Industry culture is a complex outcome of social (Beamish and Biggart 2012), institutional (Davis 1999) and economic (Powell 1990) factors. Because of the range and dynamic interplay of those factors it is not an appropriate target for industry policy, as the history of construction reform efforts that argued cultural change was necessary for industry improvement in the UK, documented over decades in a series of reports, clearly shows. When a new construction strategy was launched in 2011 the focus shifted from using public procurement to foster cultural change to requiring BIM on public projects, and over the next decade succeeded in increasing the use of BIM to around half of firms and the majority of public projects. Despite all the claims made for BIM changing industry culture and increasing collaboration (BCG 2017), if it were to come about it would be as a consequence not a cause of industry improvement from the construction strategy.

Policies that bring together issues around productivity, innovation, skills and technology do not have to be original or innovative to be useful and effective (Chang and Andreoni 2020). The construction strategy applied to all firms involved in projects, and thus included designers, consultants and suppliers as well as contractors and subcontractors, and targeted technology adoption not their separate cultures. The differences in the cultures account for the differing rates of uptake found across these firms and industries. Also, national and local governments, universities, regulators and industry bodies were all given significant but loosely specified roles in these policies to support industry engagement. Achieving policy goals requires a great deal of coordination, determination and long-term commitment (Aiginger and Rodrik 2020), qualities not always associated with government industry policy, and over the decade since the UK government launched a new Industry Strategy and the Construction Industry Strategy there was investment in capability, new standards were developed and BIM requirements increased. This new conception and practice of industry policy was about collaboration between the public and private sectors, rather than imposing unrealistic outcomes on the industry.

References

Aiginger, K. and Rodrik, D. (2020). Rebirth of Industrial Policy and an Agenda for the Twenty-first Century, Journal of Industry, Competition and Trade, 20:189–207.

Beamish, T. D and Biggart, N. W. (2012) The role of social heuristics in project-centred production networks: insights from the commercial construction industry, Engineering Project Organization Journal, 2:1-2,

BCG, (2017). Digital in Engineering and Construction: The Transformative Power of Building Information Modeling, Boston Consulting Group.

Carroll, P. (2010) Does regulatory impact assessment lead to better policy? Policy & Society, 29:2,

Chang, H-J. and Andreoni, A. (2020). Industrial Policy in the 21st Century, Development and Change, 51(2): 324–351.

Davis, H. (1999). The Culture of Building, New York: Oxford University Press.

Fernie, S., Leiringer, R. and Thorpe, T. (2006). Rethinking change in construction: a critical perspective. Building Research & Information, 34(2), 91-103.

Murray, M. and Langford, D. (2003). Construction Reports, Oxford: Wiley-Blackwell.

National Audit Office (2001) Modernising Construction, National Audit Office London: The Stationery Office.

Powell, W. (1990). Neither market nor hierarchy: network forms of organization. Research in Organizational Behavior, 12: 295–336.

Simmons, R. (2015) Constraints on evidence-based policy: insights from government practices, Building Research & Information, 43:4,

Strategic Forum for Construction, (2002) Accelerating Change, Rethinking Construction. London:

Wolstenholme, A. (2009). Never Waste a Good Crisis: A review of progress since rethinking construction and thoughts for our future, London: Construction Excellence.

Wond, T. and Macaulay, M. (2010). Evaluating local implementation: An evidence-based approach. Policy & Society, 29:2, 161-169.